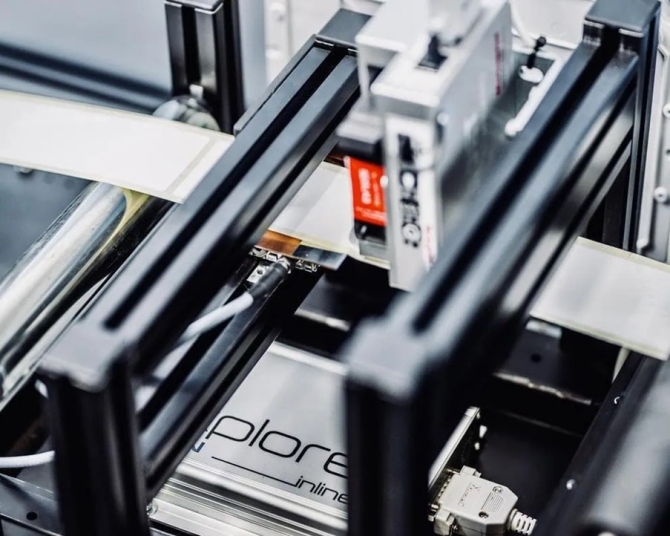

Tamarack presents CISC RAIN Xplorer Inline system

Click on image to download high resolution version

The single step solution will be shown at the Tamarack booth at Labelexpo Americas 2024.

Tamarack Products was founded in 1969 and is a leading global manufacturer of specialized equipment used in the packaging, label and business form industries. Recognized worldwide for providing high-quality machinery, Tamarack designs, manufactures, and provides exceptional after-sale support for converters who need to insert RFID inlays, patch windows to folding cartons, and add tapes/laminates to business forms and direct mail.

At Labelexpo Americas 2024, in Tamarack booth #5116, a CISC RAIN Xplorer Inline system will demonstrate two-lane encoding, testing and locking in a single step on the Tamarack EZ-RFID Encode platform. This EZ-RFID Encode system is being introduced at Labelexpo 2024 to answer the need to encode/test/lock as a secondary process to inlay insertion. A roll of RFID labels is brought to the EZ-RFID Encode, the CISC RAIN Xplorer Inline encodes/tests/locks, an inkjet system marks any labels which do not pass the testing protocol, and then the roll is slit (if necessary) and rewound into finished RFID-enabled, fully encoded and locked, labels. All this is possible multi-lane and at speeds up to 200 FPM. To further streamline production, the CISC RAIN Xplorer Inline system can be added to Tamarack’s full line of inlay insertion equipment either as a post-press operation or inline on flexo press.

Enhancing RFID Label Integrity with the unique solution from CISC

CISC Semiconductor GmbH is an established international provider of RFID solutions from Austria also located in US.

CISC`s 25 years of experience allows them to provide both products and engineering services to their customers being represented in the Semiconductor, Automotive, Wireless Communication and RFID industry all over the world. Leading companies rely on their technology and expertise during the development of their products, satisfying the latest safety and security standards that are embedded in day to day life.

Benefits of Integrated RFID Label Production

- Streamlined Production: Speed up RFID/NFC label production and dramatically reduce manual handling with the integration of encoding, testing, and locking into a single step. This streamlined process boosts throughput, speeds up delivery, and supports rapid, large-scale production needs with consistent quality, making it ideal for fast-paced industries.

- Increased Flexibility: Customize your RFID/NFC labels effortlessly with our system’s advanced software, which allows for unique information to be encoded on each label or entire rolls as needed. This flexibility is essential for businesses that vary their product labels based on different products, batches, or regulatory demands, ensuring precise configuration without slowing down production.

- Reduced Costs: Reduce both capital investment and operational costs by eliminating the need for separate machines for encoding, testing, and locking. Our system also cuts down the costs associated with purchasing pre-encoded labels, offering a cost-efficient solution for businesses aiming to optimize their expenditures without sacrificing label quality or security.

- Enhanced Data Security: Secure your RFID/NFC labels immediately after encoding with our system that locks data as soon as it’s encoded. This enhanced security is critical for industries such as pharmaceuticals, luxury goods, and electronics, where preventing unauthorized access or modifications is paramount, ensuring every label is secure and trustworthy.

- Quality Assurance: Ensure every RFID/NFC label is accurate and functional with integrated testing during the encoding and locking process. This real-time quality assurance significantly reduces errors and defective labels, crucial for maintaining your brand’s reputation and customer trust by consistently delivering high-quality labels.

- Global Standards Compliance: Meet stringent international standards for security and functionality with our system that ensures all RFID labels are compliant. This global standards adherence is vital for businesses operating in international markets, providing peace of mind that your labels are ready for deployment anywhere in the world.

Convince yourself of this incredible solution at the TAMARACK booth #5116.